Dokra Art

Dokra Art

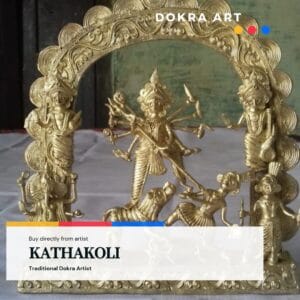

Dokra Damar tribes are the main traditional metalsmiths in West Bengal and Odisha, whose technique of lost wax casting is named after them.

Dokra Art (also called Dhokra) named after Dhokras tribe, a nomadic group that extends from Jharkhand to the southern state of West Bengal and the eastern state of Odisha. They can be traced back to a few hundred years ago when they traveled extensively, going as far as Kerala and Rajasthan.

Dokra (also spelt Dokra) is non–ferrous metal casting using the lost-wax casting technique. This sort of metal casting has been used in India for over 4,000 years and is still used. One of the earliest known lost wax artefacts is the dancing girl of Mohenjo-daro.

There are two main processes of lost wax casting: solid casting and hollow casting. While the former is predominant in the south of India the latter is more common in Central and Eastern India.

Solid casting is one of the most common techniques in creating an impression mould and only requires a solid piece of wax. Hollow casting, on the other hand, uses a clay core.

The process of creating beautiful Dokra Art.

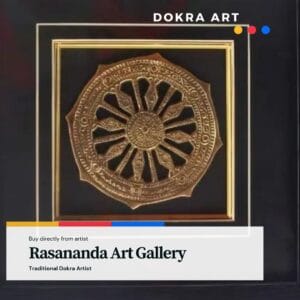

To create an intricate, high-quality Dokra Art sculpture, the artist creates a model in clay. This is coated with wax so it can be cast in metal. The lost-wax process of wax casting involves two phases: solid casting and hollow casting. The wax is made up of pure bee’s wax, resin and nut oil.

To make a wax model, the parts to be cast are first coated with hairless wax, which is shaped to form a copy of the object. Fine clay is then applied over this and left in the shade where it hardens. When this is dry, a layer of more clay is applied and holes are made in it so that metal can be poured into them.

This sculpture is created by using clay, shapes, and molds. The clay model is sun-dried and later fired in a traditional kiln – this will cause the wax to melt and flow away from the mold through the holes. To complete this step, molten metal is poured into these same holes to cool down.

The traditional process of making a brass relief starts with the sculptor creating a clay model, which is then sun-dried. This process dehydrates the clay around the object, leaving it hollowed out. When cooled down, molten brass metal is poured into it through holes in the sculpture. This causes an expensive vacuuming process which removes any droplets of metal unable